- #GEAR TOOTH GEOMETRY CALCULATOR HOW TO#

- #GEAR TOOTH GEOMETRY CALCULATOR GENERATOR#

- #GEAR TOOTH GEOMETRY CALCULATOR FULL#

- #GEAR TOOTH GEOMETRY CALCULATOR DOWNLOAD#

When you scroll down the page, you will eventually see a chart with all the constants. The formula is also in Aaen clutch tuning manual. You can replace the numbers with your own details. Here is example of skidoo 2.86 pitch track with 7 tooth.

#GEAR TOOTH GEOMETRY CALCULATOR HOW TO#

More examples, 44 / 24 = 1.83 ratio and then written and spoken as 24:44Įxample Top Speed Calculation 2008 mxzx 600RSįormula then is (8400 / 2.13) / 46.1 = 85.5mph How to calculate a drive sprocket constant Gears are displayed in text as 27:43 with a " : " to separate the values. 1:1 mph and the overdrive mph.Ĭlick on ( Engine overrevving on road (summit)) Calculate a mile per hour - a "how to"Įxample 43/27 = 1.59 ratio - Note that gears are generally discussed with mentioning the top gear first like "Twenty seven, fourty three" When using the calculator, always good to calculate the mph for both shift ratios. 88) = 92.69mphįor MXZ/REV chassis you take the 1:1 mph and divide by. or o.d.)įor XP chassis you take the 1:1 mph and divide by.

#GEAR TOOTH GEOMETRY CALCULATOR FULL#

To get the belt to go up to the rim of the primary then the sled will have to go about 93mph (full shift overdrive)Ĭalculate Full shift overdrive (O.D. The only way the belt will or should go to the top of the primary "rim" is when you are able to do the highest mph attainable with your current drive ratio.Įxample 21:45 8150 rpms with 46.1 constant will offer up 82.5 82.5 mph the belt will go up the primary clutch as high as approximately 7/8 from the rim. Remember that this is where the belt climbs to about 7/8 of an inch from the rim of the primary.

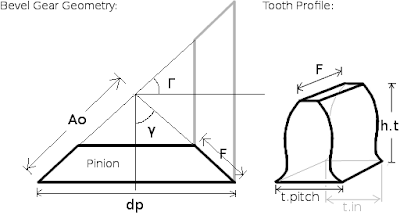

The gear calculator gives you the mph for 1:1 clutch ratio. Royal distributing in Ontario - page 137 in 2017 Catalogue Recreation supply in Saskatchewan - page 529 in 2017 catalogue - Silent chain and gears for skidoo Must be reduced for teeth with a 25-degree pressure angle having a clearance in excess of 0.250/P.Gearing Chart "Drive Sprocket Size" spreadsheet This should be avoided on highly loaded gears where the consequently reduced J factor will increase gear tooth stress excessively.ī A minimum clearance of 0.157/P may be used for the basic 20-degree and 25-degree pressure angle rack in the case of shallow root sections and use of existing hobs or cutters.Ĭ The fillet radius of the basic rack should not exceed 0.235/P for a 20-degree pressure angle rack orĠ.270/P for a 25-degree pressure angle rack for a clearance of 0.157/P. This is of particular importance on gears of few teeth or if the gear blank configuration requires the use of a small diameter shaper cutter, in which case the dedendum may need to be increased to as much as 1.45/P. Spur Gear design formula for geometry, pitch, tooth clearance and critical functional data.Įquations for Standards Spur Gears To Findįormulas for Tooth Parts, 20-and 25-degree Involute Full-depth TeethĪNSI Coarse Pitch Spur Gear Tooth Forms ANSI B6.1 To CalculateĮquations Tooth Parts, 20-and 25-degree Involute Full-depth Teeth ANSI Coarse Pitch Spur Gear Tooth Forms ANSI B6.1Ī When gears are preshave cut on a gear shaper the dedendum will usually need to be increased to 1.40/P to allow for the higher fillet trochoid produced by the shaper cutter.

#GEAR TOOTH GEOMETRY CALCULATOR DOWNLOAD#

Spur Gear and Assembly Builder - Download DXF, SVG ***

#GEAR TOOTH GEOMETRY CALCULATOR GENERATOR#

Spur Gear Calculator and Geometry Generator - Download DXF, SVG, csv file. Gear Motor Transmission Inertia Drive Calculator.Screw Worm Gear Axial Force and Thrust Calculator.Automotive Transmission Gear Ratio Equation and Calculator.Three Gears Ratios, Force Equations and Calculator.

Helical Gear and Pinion Equations and Calculator.Gear Spur Tooth Strength Equation and Calculator.Involute Spline and Serration Universal Design Calculator.Design Equations and Formula Circular Pitches and Equivalent Diametral Pitches Table

0 kommentar(er)

0 kommentar(er)